There’s a reason procurement managers keep our number on speed dial. When your primary supplier misses a deadline (and let’s be honest, that happens more than anyone likes to admit), you need someone who picks up the phone, understands your problem, and actually delivers.

That’s us. That’s STS Metals.

We’re not trying to be the biggest name in titanium and specialty alloys. We’re not chasing the latest innovation awards or competing on rock-bottom pricing. What we do is show up. Every time. On time.

Here’s who we are and what we do across our seven manufacturing facilities.

Sierra Alloys | Irwindale, California

This is where it all started back in 1974. Fifty years later, our team in Irwindale is still doing what they’ve always done best: producing forged bar, flats, and plate products with the kind of flexibility larger mills simply can’t match.

Our 75,000-square-foot facility houses two open-die forging presses, a 350-ton and a 500-ton, along with rolling, heat-treating, cutting, turning, milling, and conditioning equipment. What does that mean for you? Custom sizes in the quantities you actually need, not the minimum order a bigger operation requires to make it worth their time.

Need 50 pieces instead of 500? We’ll make it work.

TSI Titanium | Derry, Pennsylvania

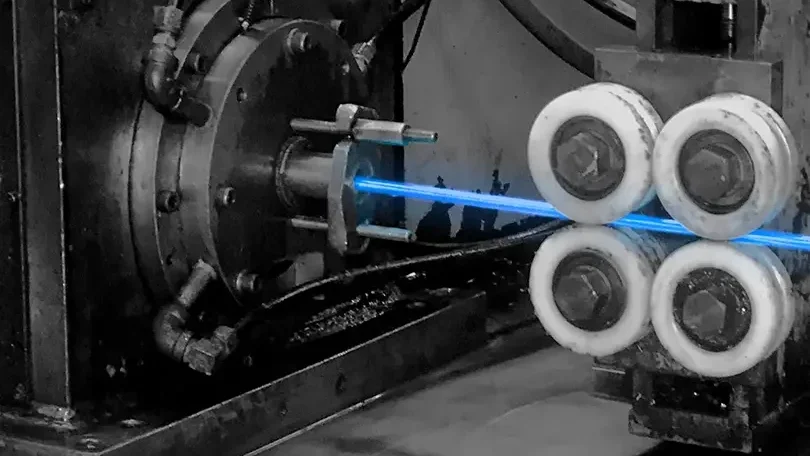

If Sierra Alloys is where we started, TSI Titanium is where we built our reputation for titanium round bar excellence. Since the mid-1970s, this Pennsylvania operation has been the backbone of our rolled and forged titanium bar production.

It’s our largest facility at over 125,000 square feet, and the equipment list tells you why: a 1,500-ton forging press feeding a multi-stand bar rolling mill with three 12-inch and six 10-inch roll stands. We forge, hot-roll, condition, heat-treat, peel, polish, cut, and finish titanium bars here, all under one roof.

For nearly fifty years, TSI has served aerospace, defense, and medical markets. The team here has seen it all, solved it all, and delivered through it all.

Sierra Sheet & Plate | Covington, Georgia

When we established Sierra Sheet & Plate in 2019, we weren’t just adding another facility to the map. We were filling a gap in our product portfolio: flat-rolled titanium plate and sheet produced with the same service-first mindset that defines everything we do.

Our 100,000-square-foot Georgia facility is a fully integrated rolling mill for titanium. We shear, surface condition, water-jet cut, heat treat, polish, pickle, and finish. Whatever your specs require. And just like our other operations, we’re built for flexibility: smaller lot sizes, quick changeovers, and lead times that won’t derail your production schedule.

Brown-Pacific | Santa Fe Springs, California

Wire and small-diameter bars for the aerospace fastener industry might sound niche. It is. And we’ve been doing it exceptionally well since 1968.

Brown-Pacific operates out of a 50,000-square-foot facility in Southern California with dedicated single-draft wire drawing lines and on-site chemical processing. We draw, shave, chemical-mill, copper plate, heat-treat, straighten, cut, and finish stainless steel and nickel alloy wire to the aerospace specifications that keep aircraft safely in the sky.

More than fifty years of experience means we’ve learned the difference between meeting specs and truly understanding what our customers need. Those aren’t always the same thing.

Brown Europe | Brive, France

When your customers operate globally, you need to meet them where they are. That’s why we established Brown Europe in France. We’re here to support European aerospace customers and programs with the same responsiveness they’d get from our domestic operations.

Having boots on the ground in Europe means shorter communication loops, easier coordination, and a team that understands European market needs firsthand. It’s one more way we make doing business with STS Metals easier.

Valley Forge | Azusa, California

The newest addition to our family, Valley Forge joined STS in late 2024 and brought with them 68 years of forging expertise. Custom open-die forgings, including large rounds, flats, and rolled rings in titanium and specialty alloy steels. That’s their wheelhouse.

Valley Forge has earned approvals from some of the most demanding aerospace, defense, and space programs in the world. Their customer-focused culture fits right in with how we operate, and their capabilities give us even more ways to support your most challenging applications.

The Philosophy

Here’s something we say internally that probably shouldn’t surprise you: “We know our role.”

We’re not trying to be ATI or TIMET. We’re not chasing market share from the giants. What we are is the reliable 10% supplier. The one you call when your primary source drops the ball, when your timeline gets compressed, or when you need someone who’ll actually work with you instead of hiding behind rigid policies.

Our CEO, David Beddome, puts it simply: we’re committed to delivering the titanium products customers need, when they need them. Not when it’s convenient for us.

That means:

Speed matters. Industry-leading lead times of 10 weeks when others quote 20 or more. We stock raw material strategically so we can respond to your urgent needs.

Service isn’t a slogan. Quick quotes, responsive communication, and a flat decision-making process where executives participate in solving problems. Not just approving them weeks later.

Flexibility is built in. Custom sizes, smaller quantities, flexible commercial terms. We’re nimble enough to work with you, not against you.

Quality is non-negotiable. AS9100D certified across all facilities, NADCAP accreditations, and supplier approvals from Boeing, Northrop Grumman, Collins Aerospace, Lockheed Martin, and more. You don’t stay qualified for decades by cutting corners.

Seven Facilities. One Standard.

What ties Sierra Alloys in California to TSI Titanium in Pennsylvania to Brown Europe in France isn’t just ownership. It’s a shared commitment to actually serving our customers instead of just selling to them.

When you work with STS Metals, you’re not working with a corporate behemoth where your order disappears into a queue. You’re working with people who answer the phone on the second ring, who understand that your production schedule doesn’t wait for anyone, and who’ve built careers on doing what they say they’ll do.

We manufacture titanium, stainless steel, nickel alloys, and specialty steels. But really, what we manufacture is peace of mind.

Ready to see the difference? Contact us to discuss your next project.